Direct Air Capture: Climate Solution or Distraction?

Climeworks Orca Plant in Iceland can capture 4,000 tonnes of CO2 annually (image: Climeworks)

Direct Air Capture, or DAC, represents a significant shift in our approach to managing carbon dioxide emissions. Unlike traditional carbon capture and storage (CCS) that targets point sources of emissions like factories or power plants, DAC can be set up anywhere, it doesn’t need to be in the same place or even at the same time as emissions are occurring. This adaptability, while advantageous, comes with significant costs.

The concentration of CO2 in ambient air is 47% higher than it was in pre-industrial times, but also around 250 times lower than in the concentrated exhaust streams of industrial facilities like cement processing or fossil power plants. This is a key distinction when comparing DAC to CCS. The technologies used in these two technologies are very similar, but the low concentration of CO2 in the atmosphere means that DAC needs to move 250 times the volume of air to get the same amount of CO2 as in point source carbon capture, and as a consequence uses much more energy.

How it works

DAC is like a giant vacuum cleaner for the atmosphere. It absorbs air and extracts carbon dioxide (CO2) from it. There are two primary techniques employed in DAC: one utilizes liquid solutions for chemical binding with CO2, and the other uses solid materials, or sorbents, for absorption.

Liquid solution method

Carbon Engineering's Liquid DAC (image: Carbon Engineering)

The liquid solution method, used by companies like Carbon Engineering in Canada, involves a well known chemical reaction. In this process, air is brought into contact with an aqueous basic solution, typically potassium hydroxide, which reacts with CO2. The reaction results in the formation of a weak acid within the solution. Drawing from basic chemistry principles, an acid and a base react to produce a salt—in this case, a carbonate salt—which effectively captures the CO2.

Carbon Engineering, for example, transforms their calcium carbonate into pellets. These pellets are then heated to approximately 900 degrees Celsius, breaking down the calcium carbonate into pure gaseous CO2 for capture and calcium oxide, which is recycled back into the reactor. This method is notably energy-intensive, primarily due to the high temperatures required for the reaction.

Solid sorbent method

The second method is the solid sorbent technique, pioneered by Climeworks in Switzerland and Global Thermostat in the US, is simpler compared to the liquid method. It uses enclosed collectors with filters made of solid sorbents that absorb CO2 from the air. Once the filter is full, the collector is closed and heated to about 100 degrees Celsius, releasing the CO2, which is then captured after cooling.

While liquid solutions offer continuous capture and are more easily scaled up, they need more energy. Solid sorbents are more modular and could be cheaper to operate but require stopping the process to regenerate the filters. The solid sorbent method is less energy-intensive than its liquid counterpart, owing to the lower temperatures needed for the release of CO2.

Current progress

Climeworks

Progress at Climeworks’ Mammoth DAC plant in Iceland

Climeworks is a leading company in the field of DAC and it has achieved notable progress with its Orca plant in Iceland, which commenced operations in September 2021. This facility boasts the capability to capture 4,000 tonnes of CO2 annually, equivalent to the emissions from approximately 870 cars in a year. Further expanding their efforts, Climeworks is currently constructing the larger Mammoth plant, also in Iceland. Once operational, this plant is expected to capture 36,000 tonnes of CO2 every year. In a unique approach within the DAC domain, Climeworks collaborates with Carbfix, a company specializing in converting captured CO2 into rock. By 2030, Climeworks aims to substantially increase its capture capacity to an impressive 1,200,000 tonnes of CO2 per year.

Global Thermostat

Global Thermostat’s kilotonne-scale unit

This company has marked a significant achievement in carbon capture with their large-scale DAC unit in Colorado. Starting operations at the end of 2022, this facility has a capacity of capturing over 1,000 tonnes of CO2 annually. January 2023 saw Global Thermostat announce a collaboration with Tokyo Gas, focusing on developing carbon capture solutions and advancing DAC technology deployment in Japan. Tokyo Gas plans to utilize the captured CO2 for applications such as methanation and carbon sequestration. Despite these developments, Global Thermostat currently faces challenges in finding applications for their captured CO2, leading to some of it being released back into the atmosphere. The company has ambitious expansion plans, aiming to grow its capture capacity to 1,500 kt CO2/year by 2030.

Carbon Engineering

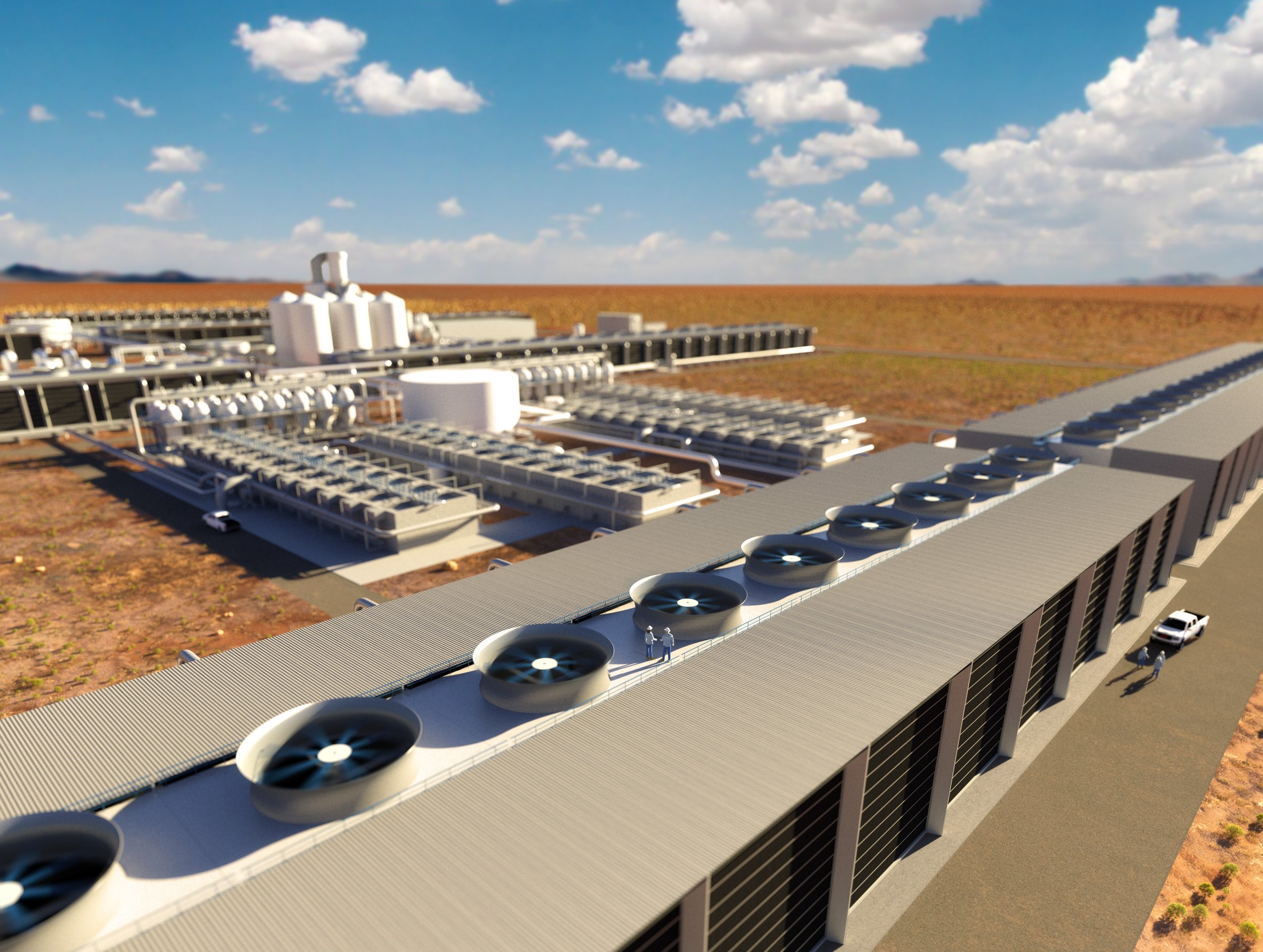

Rendering of CE’s STRATOS plant in Texas (image: Carbon Engineering)

In partnership with 1PointFive, Carbon Engineering represents another significant player in the DAC sector. Their pilot plant in Squamish, Canada, operational since 2015, captures one million tonnes of CO2 per year. However, the focus is now on their ambitious STRATOS plant in Texas, which is expected to commence operations in mid-2025. This plant, a collaboration with Oxy Low Carbon Ventures, a subsidiary of Occidental Petroleum, aims to capture 500,000 tonnes of CO2 annually. In August 2023, Occidental Petroleum further solidified its partnership by acquiring Carbon Engineering outright. The CO2 captured at the STRATOS plant is designated for geological sequestration, meaning it will be permanently stored underground. This is in contrast to other carbon storage projects by Occidental, which utilize CO2 for enhanced oil recovery. 1PointFive and Carbon Engineering plan to expand their capacity from 0.4 kt CO2/year in 2022 to 59,000 kt CO2/year by 2030.

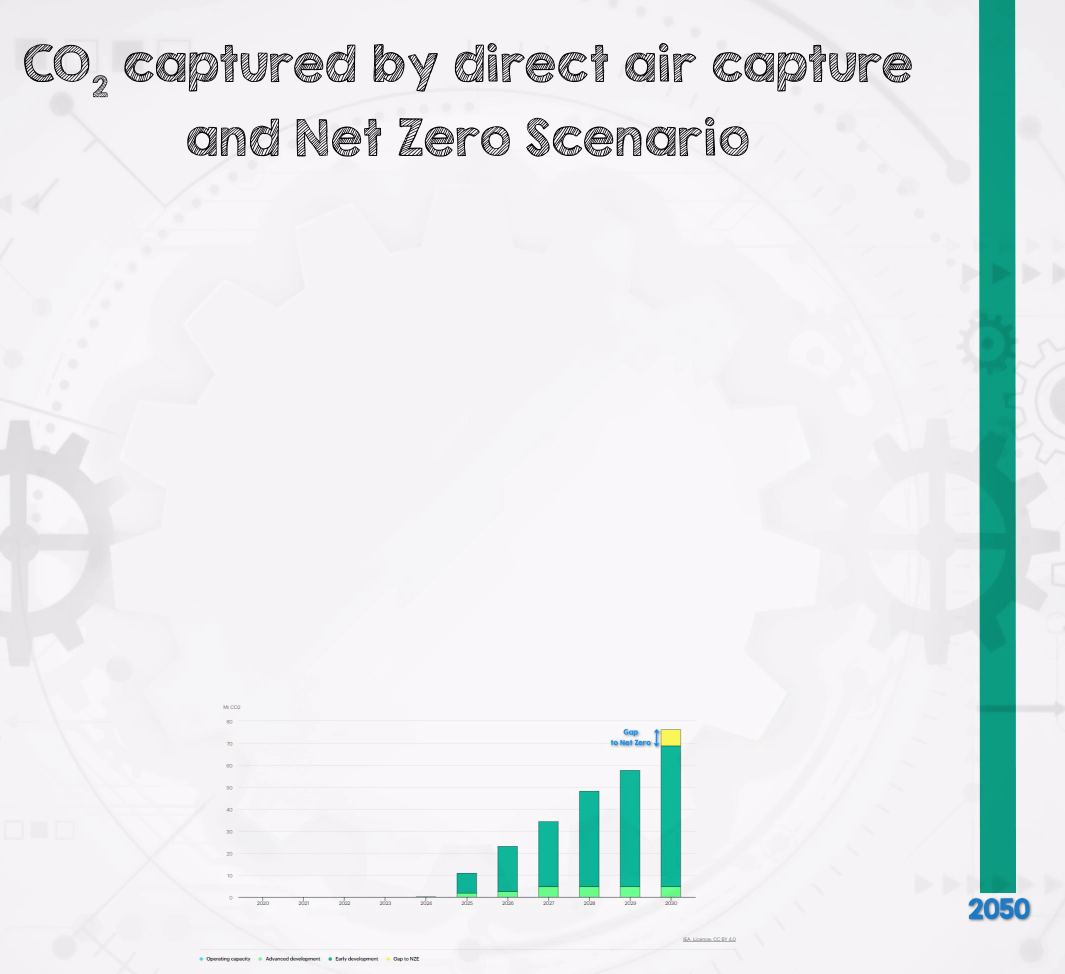

IAE DAC development path through to 2030 and 2050 (image: modified from IEA)

In the broader context of DAC, there are currently about 10,000 tonnes of carbon captured across 27 DAC plants worldwide. There are plans for at least 130 more facilities in various development stages. If these projects all come to life, we could see DAC capturing roughly 75 million tonnes (Mt) of CO2 per year by 2030. This is nearly what the International Energy Agency (IEA) suggests is necessary in their Net Zero Emissions by 2050 Scenario. For context, by 2050, this scenario anticipates the capture rate might exceed ten times this amount.

Caveats

The topic of DAC is surrounded by considerable debate, primarily concerning the appropriate utilization of captured CO2 and the potential risk of diverting attention, financial resources, and energy away from the critical objective of decarbonization.

To give you an idea of the current and projected impact of DAC, as of now, the atmosphere contains 1.7 trillion tonnes of excess CO2 compared to pre-industrial levels. Annually, we add about 37 billion tonnes of CO2 to the atmosphere. If all the planned DAC projects are completed, they would capture only about 0.2% of this additional CO2 each year. According to the International Energy Agency's (IEA) optimistic net zero scenario, by 2050, DAC might capture up to 2% of current annual emissions, which could be considered a best-case scenario. More conservative estimates suggest even this 2% target is ambitious. This indicates that DAC alone is not sufficient to counteract the significant CO2 emissions from burning fossil fuels.

Greenwashing tactic

Advocates of DAC argue that the technology is not intended to replace the need for widespread decarbonization but rather to address emissions from sectors where decarbonization is particularly challenging, such as specific segments of agriculture, aviation, and industrial processes. Except that some of the main players in DAC are explicitly saying that it is a way to continue business as usual for the oil and gas industry: Occidental CEO, Vicki Hollub, has said that “We believe that our direct air capture technology is going to be the technology that helps to preserve our industry over time […] This gives our industry a license to continue to operate for the 60, 70, 80 years that I think it’s going to be very much needed.”

It is also noteworthy that two of the three major DAC companies have strong associations with the oil and gas industry. Furthermore, projects backed by Occidental Petroleum are expected to constitute nearly 80% of the DAC capacity planned for 2030. These observations raise critical questions and implications about the motivations behind and the potential impacts of the burgeoning DAC industry.

High cost

In exploring the potential and limitations of DAC as a tool for offsetting unavoidable emissions, it's crucial to consider whether DAC represents the most effective approach. There are several alternatives, such as tree planting, bioenergy with carbon capture, mineral carbonation, and other carbon utilization methods, which are likely to be more cost-effective than DAC.

As of now, the cost of sequestering a tonne of CO2 through DAC is notably high. For instance, Climeworks, currently the only DAC company facilitating the purchase of captured CO2 from an existing project, charges around $1,400 US per tonne of CO2 for a one-off order. Given this high cost, it is evident that many sectors could achieve full decarbonization at a lower price.

Therefore, for DAC to become a viable offsetting tool, its cost must significantly decrease. While the price tag for large-scale projects might be lower than the $1,400 per tonne available to individual consumers, estimates suggest that these could range between $250 and $600 per tonne. Some optimistic projections even anticipate a reduction to $100 per tonne. However, there is a debate regarding the realistic lower limit of DAC costs, as a substantial portion of the expenses is attributed to common equipment like fans and pipes, which are unlikely to see drastic price reductions even with widespread adoption.

High carbon footprint

Even if the cost of DAC were to drop to $100 per tonne, making it an affordable option, there is a significant caveat related to energy consumption. If DAC were to become the primary method for addressing a substantial portion of our emissions, the energy requirement would be enormous. Capturing 30 billion tonnes of CO2 per year could necessitate nearly half of today’s global electricity and heat production.

Furthermore, the high energy use associated with DAC currently entails a substantial carbon footprint. Recent assessments indicate that DAC is not inherently carbon-negative. It results in net negative emissions only under specific conditions, such as utilizing waste heat for the solid adsorption process or relying on low-carbon sources of electricity and heat. In other scenarios, deploying DAC systems could paradoxically lead to a net increase in atmospheric CO2.

Challenges of Integrating DAC

But right now, our energy system isn't fully renewable, and we're in a race to replace fossil fuels with green energy sources. Introducing energy-intensive technologies like DAC into the grid could slow this process. Instead of using new renewable energy sources to phase out fossil fuel plants, we might end up using them to power DAC systems, keeping fossil fuel plants running.

The ideal scenario is to power DAC exclusively with additional renewable energy. However, even this scenario presents challenges for DAC. The resources allocated for such a project might be more effectively used in other green initiatives, such as building new wind or solar farms, developing battery technology, or other electrification projects that can prevent CO2 emissions more cost-effectively.

When considering the costs of DAC, it's crucial to note that it is generally more expensive than traditional CCS used at sources like cement factories or power plants. This higher cost is because DAC has to process much more air to extract CO2 due to its lower concentration in the atmosphere, requiring more equipment and energy. While the costs for green technologies like solar and batteries are expected to decrease, DAC's price reductions will not be as dramatic.

Limited Role of DAC in Current Climate Strategies

DAC is currently not the most effective method for reducing emissions in the atmosphere. The most efficient approach at present is to transition to clean technologies. In the context of the ongoing energy transition, there are still many opportunities for incorporating more renewable energy sources like wind and solar into electricity grids, transitioning from petrol-fueled cars to cleaner alternatives, and improving home energy efficiency through better insulation and heat pumps.

Because DAC costs more than CSS, and both of those cost more than general decarbonization, DAC is projected to tackle only about 2% of today's emissions by 2050 in net zero scenarios. It's simply cheaper to decarbonize wherever possible. However, 2% still represents a significant volume – around 740 million tonnes, or 74,000 times more than the current DAC capacity. We can't suddenly boost by 74,000 times overnight when the time comes, so gradual scaling up is necessary.

To conclude, DAC isn't the solution for major emission reductions in the near future. However, it will probably be valuable later on to tackle persistent emissions and potentially reverse climate change far in the future. To have it available then, we do need to be developing it now and running pilot projects, but is it possible to do so without supporting oil and gas companies, actively helping them to delay the energy transition?

Watch “Direct Air Capture: Climate Savior or Distraction?” on Engineering with Rosie on YouTube