What Happens When Lightning Strikes a Wind Turbine?

To us humans, getting struck by lightning is an amazingly rare occurrence. But other things get struck by lightning all the time. Things a little closer to the clouds where lightning forms. Things like wind turbines.

To wind turbines, ‘getting struck by lightning’ is less like bad luck and more like an inevitability. Standing 200 or more metres tall , wind turbines are so easy for lightning to hit that they’ve been captured attracting a bolt every three seconds during a storm. On average, each wind turbine blade gets struck 1-20 times each year, depending on how storm-prone the location.

So how does a wind turbine take hundreds of bolts of lightning over its lifetime and stay standing? In this article we’re going to find out about the tricks engineers use to make sure getting struck by lightning is no big deal.

And we’re going to find out what happens when they get it wrong.

What is Lightning?

When you were a kid, did you ever drag your feet as you walked down a carpeted corridor and then got a shock when you reached for a doorknob? That is effectively lightning on a tiny scale. Both are examples of friction causing a static electrical charge to build up. In the case of lightning, it’s ice crystals and maybe water droplets bumping against each other that build up the charge.

This charged energy can be released within a cloud, to another cloud, to the upper atmosphere, or to the ground. Although cloud-to-ground strikes are the least common type of strike, they’re the most well understood, because we’re here on the ground to observe them.

When a lightning bolt reaches towards the Earth, it’s reaching towards a big conductor. The Earth conducts electricity well, and is also enormous, so it can absorb all the charge from lightning strikes without us getting zapped every time we step on the surface.

Before I needed to understand lightning for my work, the way that I thought about lightning strikes is maybe similar to how you do: that it always chooses the easiest path to ground, and that's usually something tall and conductive. And I always wondered, how does the lightning *know* what's the easiest path? Lightning isn’t alive. It can’t see where the most conductive objects are. So if it doesn’t *know* where to strike, what makes it choose one path over another, and why is that usually the tallest object around?

In fact, the single lightning bolt pervasive in culture from cartoons to Greek mythology doesn’t tell the full story. Instead, it helps to think of lightning as a tree with a trunk and many branches. Whatever branch, or leader, makes the connection from earth to cloud first will be the main path. All the charge in the other branches will dump into the main path, and that’s when it looks like the classic Harry Potter lightning bolt. That’s negative lightning which usually flows from ground to a cloud.

Positive lightning - from the cloud to the ground - tends to be a single leader with very little branching. It doesn't really branch because positive lightning is basically hoovering electrons as it moves. There are plenty of free electrons in the atmosphere to create a path, so it doesn't need to branch out.

We talked at the start about how lightning is static electricity shock. Getting a little shock on a doorknob hurts a tiny bit, but not so much that kids don’t do it for fun. On the other hand, even if it’s not something you’ve experienced yourself, we all know that getting struck by lightning isn’t fun. So, what’s so dangerous about it?

Lightning—or any big electric charge—causes damage essentially because it makes things heat up a lot, fast. Just like ‘electricity’ is our name for charged particles moving, ‘heat’ is our name for particles moving quickly. The two are closely related and we’ll talk about the consequences for wind turbines in a minute.

On the Wind Turbine

Wind turbines, from bottom to top are made up of a foundation supporting a tower, which supports a nacelle with a generator inside and power cables run through that. Attached to the nacelle is a hub with rotor blades.

Until recently, wind turbine blades were nearly entirely made of fibreglass and balsa wood or foam, all of which are pretty good electrical insulators, meaning they do not conduct electricity well. So, based on what we said about how lightning “chooses” a path to earth, you might think that non-conductive fibreglass wind turbine blades would be safe from lightning strikes.

You’d be wrong, but at least you would be in good company with others who made that same mistake. In the 1990s hundreds of wind turbines were installed without lightning protection in Texas and Japan by a certain manufacturer whose engineers believed that since the blades aren’t conductive they wouldn’t be struck by lightning. Anecdotally, I’ve even heard that they specifically didn’t want to add a lightning protection system as they thought that would *attract* lightning. This mistake was partly due to a lack of knowledge about how lightning works and partly a false sense of security from the fact they didn’t have problems with the first turbines they installed in parts of California where lightning activity is low. Because *those* blades weren’t struck, they assumed that blades *couldn’t* get struck.

We already talked about the fact that wind turbine blades can and do get struck by lightning, and furthermore, it turns out that they get struck far more often than chance alone would dictate. This is not just because blades reach up a couple of hundred metres into the sky, but it turns out the blades’ spinning underneath a cloud has actually been documented causing strikes due to its local electric field.

So what happened to those early wind turbines that were installed under the assumption they would never get struck by lightning?

Well, it wasn’t good.

When lightning strikes an unprotected wind turbine blade, it causes the blade to heat up immensely. In the worst case you can end up with a blade on fire kind of like a Catherine wheel firework on a very grand scale.

It is rare that it gets that bad, though. A more common occurrence is that the rapid heat from a lightning strike causes punctures, charring, fibre breakage, and delamination—which is when the layers of fibreglass come apart in sheets or shards—and buckling. These might not result in spectacular firewheels, but blades with that kind of damage are not safe to continue operating. The structural damage from the strike will cause the blade to fail sooner or later. So repair crews are sent up to dangle off ropes and repair the damage.

But we now know that turbines might get struck hundreds of times in their lifetime… so in a big wind farm with hundreds of turbines we must be expecting blades to fall out of the sky every time there’s a thunder storm in the region. And I can tell you now that wind farms do not employ a rope access repair crew to go up and repair all the site’s blades after every storm. Well then, surely the first wind farm was struck down by its first thunderstorm and now the very idea of wind turbines has been shown to be unworkable, a futile machine to be destroyed within a week of powering up.

Well, that hasn’t happened. And the reason why is engineering.

Lightning Protection

We’ve covered what happens when lightning strikes an unprotected wind turbine, but after a couple of early damages due to lightning strike, wind turbine designers figured out pretty quickly that lightning protection systems are needed.

A wind turbine lightning protection system, or LPS, is similar to the way we protect buildings from lightning strikes—with a ‘Franklin rod’ or lightning attractor.

A lightning attractor is essentially a metal rod, sharpened to a point, and then connected to a conductive cable down to earth. This lightning-attractive device is connected to a structure that you don’t want to be struck by lightning. The idea is that by giving it a really attractive place to strike, lightning will strike that, and not the structure itself.

A wind turbine’s lightning protection system is very similar, with a conductive receptor or receptors attached to a thick copper or aluminium cable that runs through the blade and then through the tower down into the ground or ocean for offshore wind turbines. The way it works is that lightning attaches at the receptor at the tip of the blade, and then the energy flows through the conductive cable and into the Earth, missing the important parts of the wind turbine entirely, and without heating up any of the blade enough to damage it or catch fire.

So that works very well in theory, and it worked pretty well in practice too for decades. Until recently, wind turbine damage due to lightning strike was fairly rare, and probably due to being damaged or poorly maintained, or an abnormally large strike, or in very infrequent occurrences when lightning attached onto a part of the blade that the protection system wasn’t designed to handle.

When lightning protection systems fail, the current no longer flows through the path that the blade designers wanted it to. Instead, some of the energy hits a different part of the blade, or sparks across from one part of the blade to another. That internal sparking is called flashover, and it causes a similar type of damage to when lightning attaches to a place it’s not supposed to. That’s punctures, melting the resin that holds fibre together and splintering or splitting of fibreglass layers. It can also ignite: starting a fire on the blade that can spread to other components of the turbine if it’s not contained.

In extreme cases, lightning can be the main cause of downtime on a windfarm. Lightning damage remains the most common insurance claim from windfarm operators, accounting for up to 80% of the complaints filed with insurance companies. Over a wind turbine’s 25ish-year service life, operators expect it to be struck, protected, then partially protected, and finally show signs of damage. Lightning protection systems intend to keep wind turbines functioning, but a bolt or a hundred eroding their functionality down the track is still treated as par for the course.

In recent years, however, lightning damage has been happening more often and more severely.

Why is that? To be honest, I don’t think that anyone really knows for sure. I kind of laughed at those early wind turbine engineers who misunderstood lightning and decided that their turbines didn’t need protection. But the industry is kind of going through a similar struggle now. Lightning protection systems that have been carefully designed and tested according to international standards are still experiencing failures in the field. The reasons for this are probably due to several factors: turbines are getting taller and blades are getting longer; we’re using carbon fibre in blades to make them stiffer and carbon fibre is a great electrical conductor; and, lightning testing is not a very good approximation of real lightning strikes. We’ll go through each of these now, starting with testing.

We can't recreate a lightning strike in a lab that matches what a cloud does. Pretty much every lightning engineer working on wind turbines will tell you that it is much easier to design a system that will pass lab tests and certification than it is to design a system that will reliably protect turbines from lightning damage in the field.

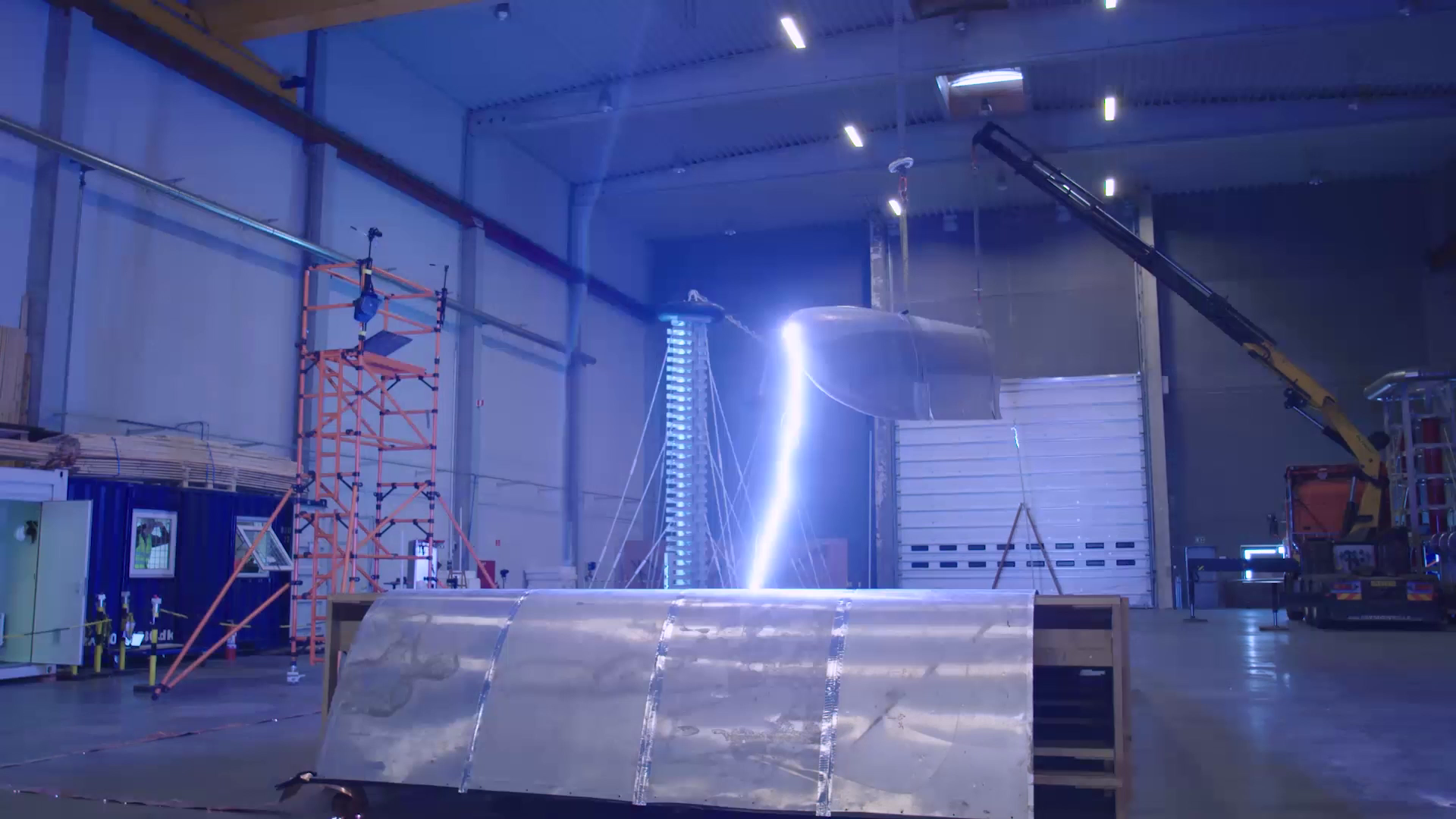

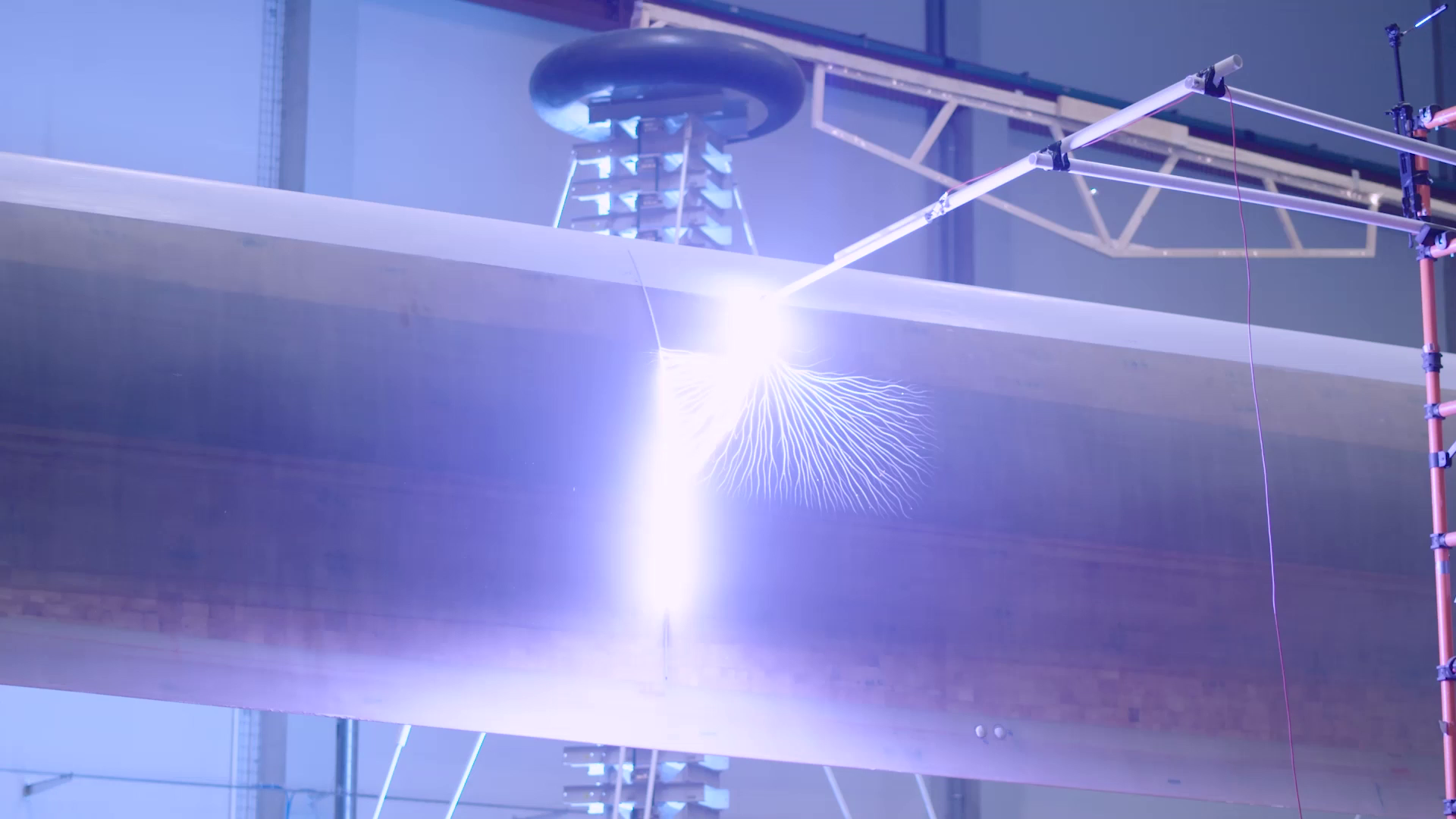

When testing in the lab, test engineers will simulate individual aspects of a lightning strike. On the largest scale, they take a real blade, cut off the last twenty-ish metres or whatever will fit in the test facility. And to that blade piece, they’ll do a high current test, to ensure the current travels from the tip receptor all the way down the copper cable instead of sparking off into other parts of the blade. And then separately, they perform high voltage testing to see where lightning attaches to a blade. A real lightning strike obviously has high current and high voltage at the same time, but the amount of power needed for that is way beyond what it feasible for the lab.

Up to 200,000 volts and 200 kA is applied during testing, which is lower than the 300 million volts and 30,000A delivered in a real lightning strike. But that’s not even the main problem. The main issue causing blade damage during a lightning strike is its specific energy, how fast the lightning’s energy is delivered. Delivering the same amount of energy quickly is much more damaging than if it is slower. And here again, the lab just can’t match reality.

And there are other compromises made based on what is achievable inside in a lab. First, lab tests are on shiny and new blades and lightning protection systems. They can’t predict how the LPS will fare halfway into its lifespan, where dust has accumulated on surfaces, strain from aerodynamic loads has caused tiny cracks in the blade resin and after having already endured fifty of its couple of hundred lightning strikes.

Second, it’s just the last part of the blade that’s tested and so the charge attaches more predictably in the lab than in the field. The blade sits stationary on a test rig rather than rotating like it does outside. And it turns out that matters, because recently we’re starting to learn that the way the air moves around a turning blade has a lot to do with how and where lightning attaches.

All of these things can affect where lightning attaches and how likely it is to flash over from where the current is supposed to go, to somewhere it shouldn’t.

I spoke to Allen Hall from Weather Guard Lightning Tech about why he thinks that there’s such a gap between testing required for certification and reality. He told me:

“We need to stop thinking about lightning as electrical wiring and start thinking about it as a compressible fluid. A lightning channel can actually be moved around by the wind. What happens for the 1 to 2 seconds a lightning channel has to follow a blade around its path of rotation? Does the lightning stay attached to the receptor or does the airflow and turbulence push it off the receptor? If we think about lightning as an electrical wiring problem, as in that it follows the path of least electrical resistance - then the answer is: lightning always stays attached to the receptor. If we think about lightning from an aerodynamic, thermodynamic perspective, that it is a column of really hot air, then lightning can be pushed wherever the wind wants it to go.”

So that is how lightning testing works, and what its limitations are. The next potential cause for lightning protection system failures is changes to the blades themselves. I’m sure we’ve all noticed that wind turbines are getting really big recently. This means blades are getting long and reaching further into the sky. That in itself is a likely cause of more lightning strike. But there are additional consequences of long blades. Long blades need to be stiffer to withstand the larger aerodynamic forces on them. Increasingly, wind turbine blades have been manufactured with some carbon fibre, which is stiffer than fibreglass. Unlike fibreglass, carbon fibre is electrically conductive. That means it’s more likely to be hit, but also that when lightning is in the blade there is a second attractive path for that current to flow, meaning the risk of flashover between the lightning cable and carbon fibre elements is high. And though carbon fibre can conduct electricity pretty well, the thickness of carbon fibre in a wind turbine blade is nowhere near enough to be able to take the current of a lightning strike without heating up excessively.

Lightning protection systems have changed to account for the new blade designs, with multi-receptor systems to account for the likelihood that lightning will attach at places along the blade as well as the tip, and sometimes a protective conductive layer such as a copper mesh is added to take current that would have otherwise have gone into the carbon fibre.

Image source: Polytech

These new systems are definitely protecting huge carbon fibre blades better than the older designs would have, but there simply isn’t enough operational experience and years of iterative design changes to end up at a reliable design yet. I talked about the challenges with getting lab testing to accurately reflect the realities of real world lightning strike. Lightning engineers will also run very detailed simulations to try out new designs before they sign off on a design to manufacture and test in the lab. But testing and simulations are mainly good at assessing incremental changes, not completely new designs.

We’ve talked about how lightning striking wind turbines is not as infrequent as you might think. However, it is still far from a daily occurrence and not something you can schedule. When new wind turbines are designed, the manufacturer will make a test turbine or two to install in the field and monitor over a year or two. And those test turbines will of course have the lightning protection systems in place. But one or two turbines over a year or two is not enough to ensure that the LPS will see any action at all in the test period. Once the test period is up, hundreds or thousands of turbines are manufactured and installed around the world. If there’s a problem with the LPS, it will take years before it’s clear whether the first failures are due to freakishly big lightning strikes that they were never designed to withstand, or if the LPS design is faulty. And by that time, there are probably thousands of turbines out there, and so any problem can end up incredibly expensive to fix across the whole fleet.

To windfarm operators, occasional and usually repairable lightning damage is commonplace, inevitable. But it can be costly. A German electric power company, for example, shut down and dismantled their Helgoland Island wind power plant after suffering more than $540,000 (USD) in lightning-related losses over three years of operation. And there are plenty of other examples.

If you need expert advice about lightning damage on wind turbines contact Rosemary here.

This article is also available as a video on Engineering with Rosie on YouTube. And for even more information about lightning check out the livestream with lightning engineer Allen Hall.